LV Composites is a France-based specialist in advanced composite materials, offering innovative manufacturing solutions for industrial, aeronautical, nautical, and technical applications. With a strong focus on precision engineering, customization, and performance, LV Composites supports clients from concept development to final production.

By combining material expertise, modern manufacturing technologies, and a client-centric approach, LV Composites has positioned itself as a trusted partner for high-performance composite projects.

About LV Composites

LV Composites brings together multidisciplinary skills in composite engineering, machining, and additive manufacturing. The company works closely with research teams, engineers, and industrial partners to deliver tailor-made solutions adapted to demanding technical requirements.

Their integrated workflow ensures:

- Optimized design

- Material efficiency

- High structural performance

- Fast prototyping and production cycles

Expertise in Composite Materials

High-Performance Fibres

LV Composites works with a wide range of technical fibres, including:

- Carbon fibre

- Glass fibre

- Aramid fibre

- Natural fibres

These materials are selected based on strength-to-weight ratio, durability, flexibility, and application needs.

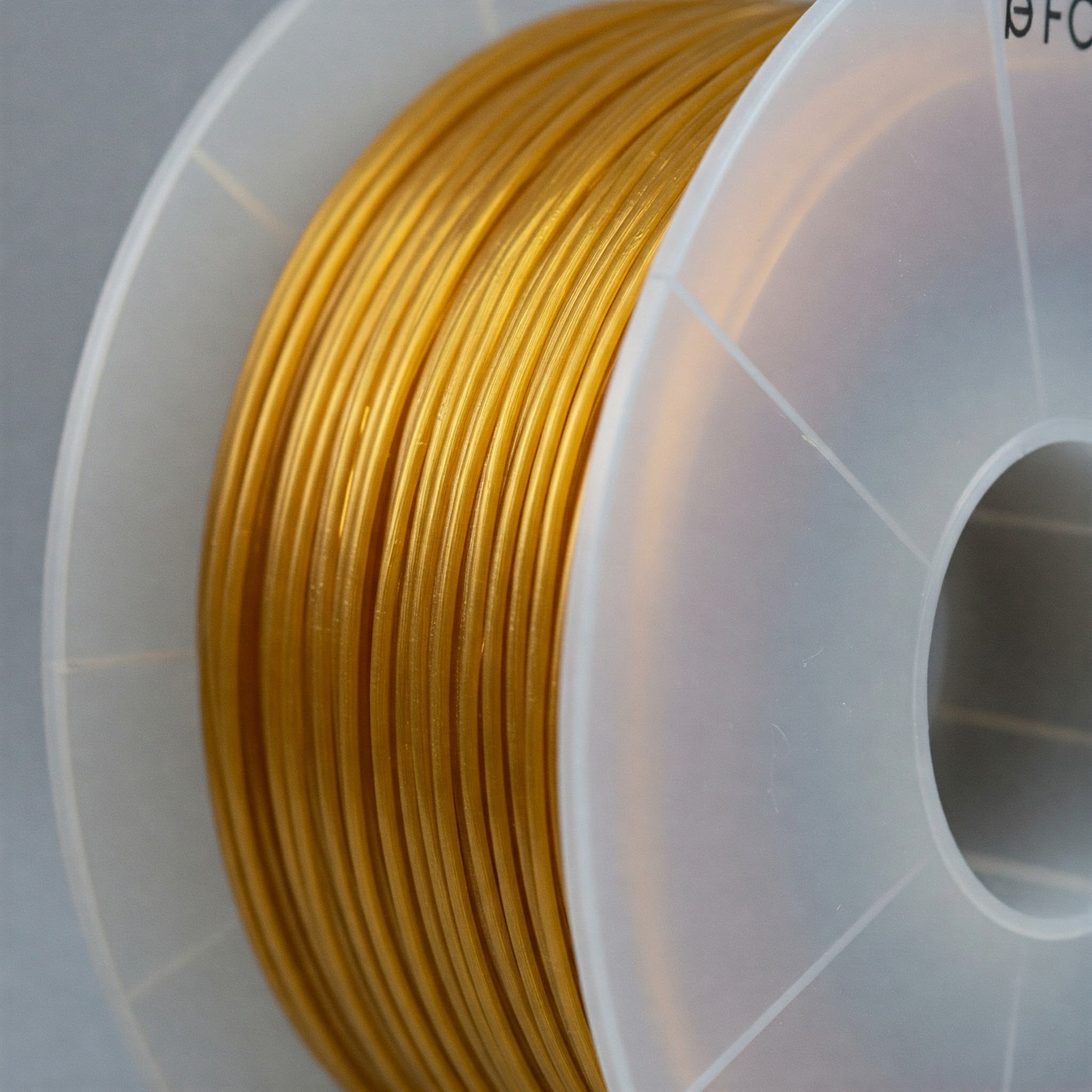

Advanced Resins & Filaments

The company also masters various resin systems and technical filaments, such as:

- Epoxy resins

- Polyester resins

- High-performance thermoplastics

- Custom composite filaments for 3D printing

This versatility allows LV Composites to meet both structural and functional performance requirements.

Composite Manufacturing Capabilities

Fibre Winding Technology

Fibre winding is one of LV Composites’ core competencies. This process is ideal for producing strong, lightweight, and highly resistant cylindrical or symmetrical components used in aerospace, industrial, and pressure-resistant applications.

Precision Machining & CNC Cutting

LV Composites offers advanced CNC machining, including:

- Milling

- Drilling

- Waterjet cutting

- Laser cutting

These processes ensure tight tolerances, repeatability, and superior surface finishes for composite and technical materials.

Additive Manufacturing & 3D Printing

With expertise in 3D printing of technical materials, LV Composites supports:

- Rapid prototyping

- Functional testing

- Small to medium series production

This capability significantly reduces development time while maintaining mechanical performance.

Industries Served

Aerospace & Aeronautics

LV Composites develops lightweight, high-strength components for aeronautical applications where performance, safety, and reliability are critical.

Nautical & Marine Applications

For the marine industry, composite materials offer excellent resistance to corrosion, moisture, and fatigue—making LV Composites an ideal partner for nautical solutions.

Industrial & Mechanical Engineering

From tooling to structural components, LV Composites supports industrial clients with custom composite parts designed for durability and efficiency.

Safety & Protective Equipment

The company also contributes to protective and defense-grade applications, offering materials engineered for impact resistance and structural integrity.

Research, Development & Prototyping

Innovation is central to LV Composites’ DNA. The company actively supports R&D projects, offering:

- Design optimization

- Material testing

- Rapid prototyping

- Technical feasibility studies

This collaborative approach enables clients to transform ideas into functional, high-performance products.

Commitment to Quality & Precision

Every project at LV Composites follows strict quality control procedures. From raw material selection to final inspection, precision and consistency are maintained throughout the manufacturing process.

Key quality principles include:

- Process traceability

- Material compliance

- Dimensional accuracy

- Performance validation

Why Choose LV Composites?

Technical Expertise

Decades of hands-on experience in composite materials and advanced manufacturing techniques.

Custom-Made Solutions

Each project is adapted to the client’s technical, functional, and budgetary needs.

Rapid Turnaround

Efficient workflows allow fast prototyping and responsive production timelines.

Multidisciplinary Capabilities

A single partner for design, manufacturing, machining, and finishing.

Sustainable & Future-Focused Manufacturing

LV Composites actively explores sustainable composite solutions, including:

- Material optimization to reduce waste

- Use of natural fibres where applicable

- Efficient manufacturing processes

This forward-thinking approach aligns innovation with environmental responsibility.

Conclusion

LV Composites stands as a reliable and innovative partner in advanced composite manufacturing. With expertise spanning fibre winding, CNC machining, 3D printing, and high-performance materials, the company supports a wide range of industries with precision-engineered solutions.

Whether for aerospace, industrial, nautical, or R&D applications, LV Composites delivers performance-driven composites designed for today’s most demanding challenges.